Project’s objectives

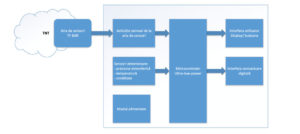

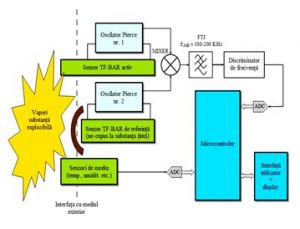

The project will develop a portable microsystem based on TF BAR sensors arrays for multiple detection of explosive substances. It will be used for technical anti-terrorist control, ensuring the security of critical infrastructures (airports, subway, governmental buildings, command centres etc.) and persons / officials participating in major public events (political, sports, cultural or social events).

The risks associated with terrorist attacks in Europe are continuously rising, therefore the necessity of a portable, fully automated detection system is very present and urgent. The system will have selective and sensitive sensors, capable of detecting traces or particles of the main explosives on various objects (parcels, vehicles, clothes) or on the skin.

The developed microsystem will detect both most of the explosives used in manufacturing small IEDs (Improvised Explosive Devices) (TATP, HMTD, TNT, RDX – trinitro-triazinano, NG – nitroglycerin, EGDN – ethylene glycol dinitrate) and ammonium nitrate (AN), the most usual compound used in ambush vehicles attacks (ANFO – ammonium nitrate fuel oil, Astrolite, Tannerite).