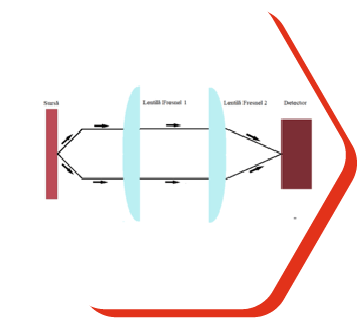

In Project 3, taking into account the results obtained in the previous stages, the optical components of the detection system were optimized and the corresponding experimental models were made.

Moreover, an experimental model for the hazardous gas detection system was developed. The optimized optical components were characterized by the experimental procedures developed in the previous stages, for each component being prepared a test report.

For the characterization in optical power and wavelength of the detection system, an experimental procedure was developed and the preliminary experimental procedure was drawn up, the final variant being performed at the next stage. Because it is desired to test the detection system and from the point of view of its resistance to shocks, the experimental assembly of the vibration test was performed and a variant of the measurement procedure was drawn up.

The results obtained at this stage were presented at 2 international conferences. Also, a patent application was filed by the two partner organizations, a scientific paper was published in an ISI conference volume, a paper was published in an ISI journal.